PRODUCTS

Q2 offers a complete line of down hole rod pumps, along with engineering, technical and manufacturing support, to meet and exceed the demands of our customers.

SERVICES

Q2 specializes exclusively in sales, service and manufacturing of down hole rod pumps. Years of experience together with innovative ideas solidify us as leaders in artificial lift.

LOCATIONS

We have a total of 40+ service and repair facilities located throughout Canada and the USA. Q2 head office and manufacturing facility is located in Red Deer, AB, Canada.

Q2-TRAK

Q2-Trak Well Tracking System allows our customers the ability to access all data collected on their rod pump inventory & repairs through our field locations.

WELCOME TO Q2 ARTIFICIAL LIFT SERVICES

ARTIFICIAL LIFT SERVICES | DOWN HOLE ROD PUMP SPECIALISTS

Q2 Artificial Lift Services (ALS) is a World Class Rod Lift System Solutions company that specializes in the sales, service, engineering and manufacturing of down hole reciprocating pumps. We are a fully integrated company with over 40+ repair and service locations strategically located across Western Canada and the United States.

Q2 Artificial Lift Services opened in December 2016 in Red Deer, Alberta Canada. Our Senior Management team has an average of 20+ years working in the oilfield business. Years of experience coupled with innovative new ideas, solidify us as leaders in the industry.

Our state of the art facilities combined have grown to 118,000 sq. ft. with 80,000 sq. ft. of new manufacturing facility and we offer a heat treated tubing process in our Red Deer facility.

Our Service, Quality, Knowledge and Innovation is what sets us apart.

Q2 offers our customers a full line of Down hole rod pump components and accessories that are manufactured in house. With Q2 having the ability to control all manufacture procedures, this enables us to provide a world class product.

Coupled with our service locations along with our engineering and technical support, Q2 can fulfill all of our customers needs to minimize their overall costs and maximize their production demands, while supplying them with new technology and innovative ideas. This singular focus and full integration of down hole rod pumps sets us apart from our competitors and solidifies Q2 ALS as the industry leader.

SERVICES

Q2 Artificial Lift Services is an oilfield services company specializing in one thing- Sales and Service of World Class Rod Lift System Solutions

Our goal is not to be the largest supplier, our vision is becoming a Worldwide Supplier of Choice.

FIELD LOCATIONS

We have over 40+ field facilities providing sales & services across North America. All pump technicians ensure your pumps are repaired professionally and efficiently.

ENGINEERING & TECHNICAL SUPPORT

This engineering and technical support is, along with our knowledge of down hole pumping systems, part of our services offered to our client base.

MANUFACTURING

We offer world class manufacturing in our new 80,000 sq. ft. state of the art facility. We offer in-house chroming, spray metal welding, heat treating and CNC’s.

PUMP SCHOOLS & SEMINARS

We have the ability to train customer field personnel on proper down hole pumping procedures through our pump schools and can offer solutions to enhance long term productivity.

Q2-TRAK SOFTWARE

Q2-Trak is the next generation well tracking system helping our customers collect & maintain their bottom hole pump data. Q2-Trak also allows our customers the ability to access all data collected through our field facilities.

OUR PRODUCTS

API INSERT PUMPS

Q2 ALS offers a variety of bottom hole pump designs that will fit all of our customers requirements. We manufacture standard API and non – API Oversized Pumps.

SPECIALTY PUMPS

Q2 has several designs that can help our customers produce gas and sand laden fluids. Q2 can design a pump that will fit whatever application our customers require.

Q2-FLOW CAGE

Q2-Flow Cage which utilizes the Tangent Flow technology. This cage helps in pressure drop areas through the cage which will help in the overall production of pump.

SPECIALTY TUBING & SUCKER RODS

Q2 has 2 types of specialized tubing that promote longevity where premature failures are consistent in severe dogleg and horizontal applications. Our Q2-HTT and CPT tubing will give our customers longevity due to increased hardness on the ID of tubing. Each style of tubing will offer a well specific solution.

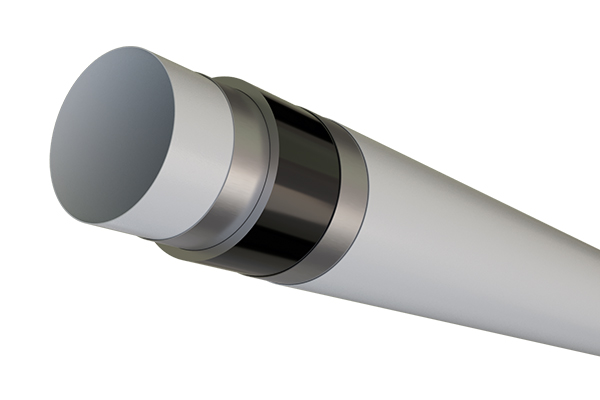

PLUNGERS

Q2 offers a full line of plungers including Spray Metal, Pressure Activated and Tungsten Sprayed. Q2 Offers many styles of sand and gas plungers that we can design to our customers conditions.

BARRELS

Q2 offers a full line of barrels including steel chrome, stainless steel and Ni-Carb, Q2 has a proprietary chroming process that gives us advantages over conventional chrome plating.

CAGES & FITTINGS

Q2 offers a full line of cages from our full flow, stellite lined to out New Technology Q2-Flow cage. Q2 manufactures all of our components in house to meet and exceed all API standards.

ACCESSORIES

Q2 manufactures a variety of accessories for our bottom hole pumps including gas relief tools, top seals, shear tools, specialty rod guides, wiper systems and on off tools.

POLISHED RODS

Q2 ALS manufactures and sells several types of polished rods that will adapt to every application from moderate to severe conditions with high tensile strengths.

“At Q2 Artificial Lift Services our values are Team Pride, Safety First, Growth through excellence, Quality at the source, integrity and to honor our commitments. Our Mission is to become a fully integrated supplier of choice in down hole pumps through our responsiveness in delivering exceptional quality in our products & services from the field store locations across Canada and the United States through the technical sales team and engineering to the customer where we meet or exceed their expectations. My Vision is that Q2 ALS will be a world-class organization recognized for our people and performance.”

Doug Quinn – President

We are your Down Hole Rod Pump Specialists | Call US today : (403) 343.8802

Q2 Artifical Lift Services is Technology & Innovation in Motion

RECENT NEWS

FEATURED PRODUCT

NEW PRODUCT

Q2 Premium Sand Twister

This video illustrates our new Premium Sand Twister Pump utilizing two of our patented technologies.